Physical chemical analysis of the leaves of eucalyptus camaldulensis and its hydrolizate as a substrate in the production of xylitol

DOI:

https://doi.org/10.31908/19098367.3553Keywords:

physicochemical parameters, process biotechnology, hydrolysis, xylitol, eucalyptusAbstract

Eucalyptus is used as a source of renewable energy and the development of several products at industrial level; wasted leaves and branches whose content of lignocellulosic material can be converted into raw material product with specifi c applications, therefore, physicochemical analysis of leaves and its hydrolyzate was performed to determine the viability of the substrate in the production of xylitol, through biotechnological processes. Physicochemical parameters such as humidity, water activity (Aw), total soluble solids (° Brix), thermogravimetry (TGA), and infrared (IR FT) to the plant sample, and titratable acidity, pH, reducing sugars (DNS) were evaluated, ° Brix and infrared to hydrolysates, showing results led to the conclusion that the residual biomass Eucalyptus camaldulensis, is a potential substrate in the production of xylitol from biotechnological reduction of fermentable sugars such as D-xylose utilizing yeasts Candida.

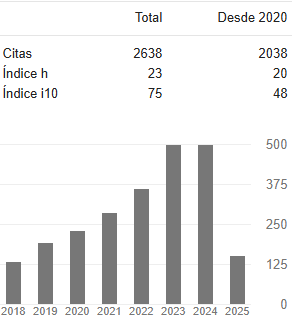

Downloads

References

Alonso, J.R. (2010). Edulcorantes Naturales. La Granja, 12(2), 3-12

MECAS. (2012)04 – Alternative Sweeteners in a high sugar price environment. International sugar organization.

Qunyi T., Qian X. & Loong-T. (2012). Effects of glycerol, sorbitol, xylitol and fructose plasticisers on mechanical and moisture barrier properties of pullulan–alginate–carboxymethylcellulose blend films. International Journal of Food Science and Technology. 38 (2) pp.1-9

Nielsen, S. S. (2011). Food Analysis Laboratory Manual. Editorial Springer. London. pp 35-43.

Rafiqul, I. S. M., & Sakinah, A. M. M. (2013). Processes for the Production of Xylitol. Food Reviews International, 29 (2) pp. 127-156.

Rouessac, F., & and Rouessac, A. (2007). Chemical Analysis. 2nd ed. West Sussex: Wiley

Gondim, A. Lys M. (2003). Aplicaciones del Xilitol en otorrinolaringología. IV Manual de otorrinopediatría da IAPO.

Mussato, S. I., & Roberto, I. C. (2004). Xilitol: Edulcorante com efeitos benéficos para a saúde humana. Revista Brasileira de Ciencias Farmacéuticas, 38(4), 401-413.

Sánchez, M. (s.f.). Experiencia Argentina en el uso de la madera de Eucalipto. Seminário Internacional de Utilização da Madeira de Eucalipto para Serraria. (1995), Sao Paulo. pp. 1-18.

Vanegas, I. A., Yepes, M., & Ruiz, O. S. (2004). Producción de xilitol a partir de levaduras nativas. Revista colombiana de biotecnología, (6), 31-36.

Organización Internacional del Azúcar. (2012). Edulcorantes alternativos en un contexto de altos precios del azúcar. Organización Internacional del Azúcar, MECAS (12) pp.4-12.

Santos, E., Cancino, N., Yenque, J., Ramírez D., & Palomino, M. (2005). El ultrasonido y su aplicación. Revista de la facultad de ingeniería industrial (UNMSM), (8), 25-28.

Uribe, A. (2007). Caracterización fisiológica de levaduras aisladas de la filosfera de mora. (Tesis de pregrado). Universidad Javeriana, Bogotá, Colombia.

Cuervo, L., Folch, J. L., & Quiroz, R. E. (2009) Lignocelulosa Como Fuente de Azúcares Para la Producción de Etanol. Revista Mexicana de Biotecnología, 13(3), 11-25.

Kim, J. H., Han, K. C., Koh, Y. H., Ryu, Y. W., & Seo, J. H. (2002). Optimization of fed-batch fermentation for xilitol production by candida tropicalis. Journal of industrial Microbiology & Biotechnology (29), 16-19.

Saval, S. (2012). Aprovechamiento de residuos agroindustriales: Pasado, presente y futuro. Biotecnología, (16), 14 - 46

Downloads

Published

Issue

Section

License

Copyright (c) 2018 Entre ciencia e ingeniería

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.