Six Sigma in The Supply Chain

DOI:

https://doi.org/10.31908/19098367.673Keywords:

Supply Chain, Six SigmaAbstract

This article aims to present the state of art of the use of Six Sigma in the supply chain. As a result of the article, we identify a research opportunity related to the construction of a methodology to support the design and improvement of supply chains and logistics systems generically. Furthermore, we analyzed the opportunity of using the design of experiments and others statistical techniques in order to designor improve efficient processes with statistical basis.

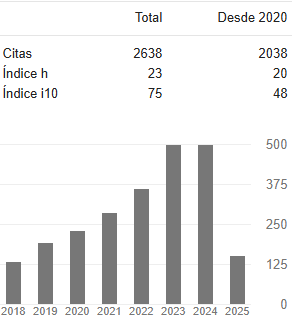

Downloads

References

R. Caulcutt, ”Why is Six Sigma so successful?”; En: Journal of Applied Statistics, vol. 28, nº. 3, 2001, pp. 301-319.

J. Freiesleben, “Communicating six sigma’s benefits to top management”, Measuring Business Excellence, vol. 10, nº. 2, 2006, pp. 19-27.

R.McAdam y S.Hazlett, S, “An absorptive capacity interpretation of Six Sigma”;Journal of Manufacturing Technology Management, vol. 21, nº. 5, 2010, pp. 624-645.

S. Cohen, y J.Rousse, Strategic supply chain management. The United States: McGraw-Hill Professional, 2005,p. 128.

D.Lambert, Supply chain management. The United States: Supply Chain Management Inst, 2008, p.156.

M.Singer, P.Donoso, y G.Konstantinidis,”Who wants to break the hockey-stick sales pattern in the supply chain?”, Annals of Operations Research, vol. 169, nº. 1, 2009, pp. 131-147.

M. Naganuma,M, T. Sakuma, K. Igarashi y N. Katsube,N. Supply chain evaluation system, method, and program.The United States, 2009, p. 12

E. Frazelle. World-class warehousing and material handling. The United States: McGraw-Hill Professional, 2002, p.56.

J. Metzer. Supply chain management. New Delhi: SAGE, 2001, p. 79.

A.Correa y R.Gómez, R.”Tecnologías de Información en la Cadena de suministro”, Revista DYNA, Vol 1, nº 57, 2009, pp 37-48.

P.Toktas-Palut y F. Ülengin, “Coordination in a two-stage capacitated supply chain with multiple suppliers”. European Journal of Operational Research. Vol 12, nº 1, 2011, pp 43-53.

M. Bashiri y M.Tabrizi .”Supply chain design: A holistic approach”, Expert Systems with Applications, vol. 37, nº. 1, 2010, pp. 688-693.

A. gapiou, L. Clausen, R. Flanagan, G. Norman y D. Notman.”The role of logistics in the materials flow control process” Construction Management and Economics, vol. 16, nº. 2, 1998, pp. 131-142.

R.Ballou. Logística. México: Pearson Educación, 2004, p. 121.

J. Langford. Logistics: principles and applications. The United States: McGraw-Hill Professional, 2006, p. 134.

Council of Supply Chain Management Professionals. Supply Chain Management. The United States: CSCM, 2006, p.15.

A. R. Hofer y A. M. Knemeyer, “Controlling for logistics complexity: scale development and validation,” The International Journal of Logistics Management, vol. 20, nº. 2, 2009, pp. 187-200.

M. Abrahamsson, N.Aldin, y F. Stahre, F. “Logistics platforms for improved strategic flexibility”. International Journal of Logistics Research and Applications: A Leading Journal of Supply Chain Management, vol. 6, nº. 3, 2003. pp. 85-93.

S.Friday-Stroud y J. Sutterfield. “A conceptual framework for integrating six-sigma and strategic management methodologies to quantify decision making”, The TQM Magazine, vol. 19, nº. 6, 2007, pp 561-571.

H. Harrington. Mejoramiento de los procesos de la empresa. México: McGraw-Hill, 1995, pp. 23.

G.Knowles, L.Whicker, J.Femat, y F. Canales. “A conceptual model for the application of Six Sigma methodologies to supply chain improvement”, International Journal of Logistics Research and Applications: A Leading Journal of Supply Chain Management, vol. 8, nº. 1, 2005, pp. 51.

E.Jones, E. Parast, E y S. Adams. “Framework for effective Six Sigma implementation”. Total Quality Management & Business Excellence, vol. 21, nº. 4, 2010. pp. 415.

J.Van Iwaarden,J, T. Van der Wiele, B.Dale,R. Williams y B.Bertsch. “The Six Sigma improvement approach: a transnational comparison”, International Journal of Production Research, vol. 46, nº. 23, 2008, pp. 6739-6746.

K.Chen, C.Lin y S.Chen. “Applying Six-Sigma methodology in constructing the quick response of a case reporting system”; En: Total Quality Management & Business Excellence, vol. 19, nº. 4, 2008, pp. 381-392.

A. Haikonen, T. Savolainen y P. Järvinen. Exploring Six Sigma and CI capability development: preliminary case study findings on management role; En: Journal of Manufacturing Technology Management, vol. 15, nº. 4, 2004, pp. 369-378.

T. Fontalvo El método: Enfoque sistémico convergente a la calidad. Bogotá: ASD 2000, 2010, p.124

M.Pepper, y T. Spedding,T.”The evolution of lean Six Sigma”, International Journal of Quality & Reliability Management, vol. 27, nº 2, 2010, pp. 138-155.

M. Zeydan, M.”A guide to lean six sigma management skills”, International Journal of Production Research, vol. 48, nº 14, 2010, pp. 4327-4334.

C. Thevnin. “Effective management commitment enhances six sigma success”, Handbook of Business Strategy, vol. 5, nº.1, 2004, pp. 195- 200.

N. Dedhia,N. “Six sigma basics”, Total Quality Management & Business Excellence, vol. 16, nº 5, 2005, pp. 567-577.

V.Shanmugam. ”Six Sigma Cup: Establishing Ground Rules for Successful Six Sigma Deployment”, Total Quality Management & Business Excellence, vol. 18, nº 1, 2007, pp 77-84.

X, Zou y W, Lee,W. “A study of knowledge flow in Six Sigma teams in a Chinese manufacturing enterprise”, VINE, vol. 40, nº.3, 2010, pp 390-403.

P. Miguel y J. Andrietta, J. “Benchmarking Six Sigma application in Brazil: Best practices in the use of the methodology”. Benchmarking: An International Journal, vol. 16, nº 1, 2009, pp. 124- 134.

Y.Park, H.Choi y J. Baik. “ A Framework for the Use of Six Sigma Tools in PSP/TSP,” in Software Engineering Research,”. Management & Applications, 2007. SERA 2007.5th ACIS International Conference on, 2007, pp 807-814.

J.Ravichandran. “Six-Sigma Milestone: An Overall Sigma Level of an Organization”, Total Quality Management & Business Excellence, vol. 17, nº 8, 2006, pp 973-983.

J. De Feo,J y Z. Bar-El. “Creating strategic change more efficiently with a new Design for Six Sigma process,” Journal of Change Management, vol. 3, 2001, nº 1, pp 60-80.

Y.Narahari, N.Viswanadham, y R.Bhattacharya, “Design of synchronized supply chains: a six sigma tolerancing approach,” in Robotics and Automation, 2000. Proceedings. ICRA ‘00. 2000, pp. 1151-1156.

D.Garg, Y. Narahari y N. Viswanadham, “Design of six sigma supply chains”, in Robotics and Automation, 2003. Proceedings. ICRA ‘03 conf. 2003, pp. 1737-1742.

T. Dasgupta, “Using the six-sigma metric to measure and improve the performance of a supply chain,” Total Quality Management & Business Excellence, vol. 14, nº. 3, 2003, pp. 355.

G.Knowles, L.Whicker, H.Femat, y F. Canales,“A conceptual model for the application of Six Sigma methodologies to supply chain improvement”; International Journal of Logistics Research and Applications: A Leading Journal of Supply Chain Management, vol. 8, nº. 1, 2005, pp 51-67.

J. Xu,J. “Six Sigma-Based Methodology for Performance Measurement of a Supply Chain,” Wireless Communications, Networking and Mobile Computing 2008. WiCOM ‘08. 4th International Conf, 2008, pp 1-4

Z. Zhang, X.Yan, y Z.Xuan.(2010) “Research on the application of Six-Sigma’s method to Supply Chain Management,” in Automation and Logistics (ICAL), 2010 conf, pp. 76-81

S.Kuik, S.Nagalingam,Y.Amer, y Y.Saw. “Implementation of Six Sigma methodology to improve supply chain network in the context of Malaysian manufacturing industries”, Supply Chain Management and Information Systems (SCMIS), 2010. pp. 1-8.

P. Sutherland. “Assessment of industrial distribution system reliability using Six Sigma techniques”, In 2000 Industrial and Commercial Power Systems Technical Conf., 2000, pp. 67-74.

F. Wang,F, T. Du y E. Li.” Applying Six-Sigma to Supplier Development”, Total Quality Management & Business Excellence, vol. 15, nº 9, 2004, pp 1217-1225.

P. Das. “Reduction in delay in procurement of materials using Six Sigma philosophy”, Total Quality Management & Business Excellence, vol. 16, nº. 5, 2005, pp 645-653.

A.Mukhopadhyay y S. Ray. “Reduction of Yarn Packing Defects Using Six Sigma Methods: A Case Study”. Quality Engineering, vol. 18, nº 2, 2006, pp 189-198.

Z. Yuan, X. Yan y W. Zhen “Research on the Application of Six Sigma Method in Logistic Corporation”; Automation and Logistics, 2007, pp 890-893.

M. Chen y J. Lyu. “A Lean Six-Sigma approach to touch panel quality improvement”,Production Planning & Control: The Management of Operations, vol 20, nº 5, 2009, pp 445-453

T. Allen.Introduction to Engineering Statistics and Lean Sigma, London, Springer, 2010, p.156.

Downloads

Published

Issue

Section

License

Copyright (c) 2019 Entre ciencia e ingeniería

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.